Have hardware questions?

Need help finding items?

Want to get a quote?

Speak to one of our friendly

and knowledgeable customer

service reps at

800 344 6437

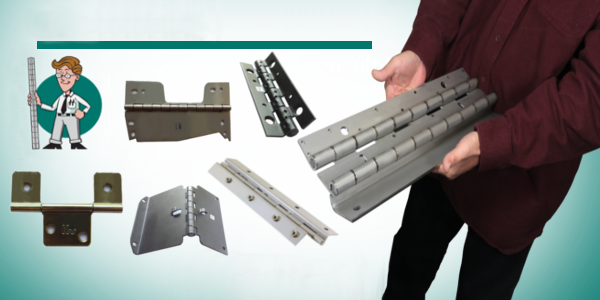

Most Popular Categories

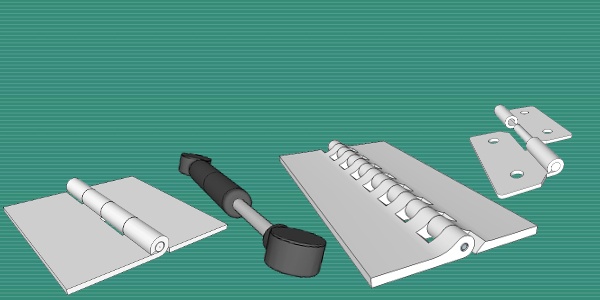

Hinges, Gas Springs, Dampers, Casters, Latches, Catches, Handles, and So Much More

Here's why people love Guden:

-

Expertise

- Since 1920, Guden and its knowledgeable hinge customer service team have been helping people get the perfect custom hinges and hardware that they need. -

Quality

- Guden's quality assurance team and ISO 9001 compliance guarantee that you'll get a quality product every time. -

Variety

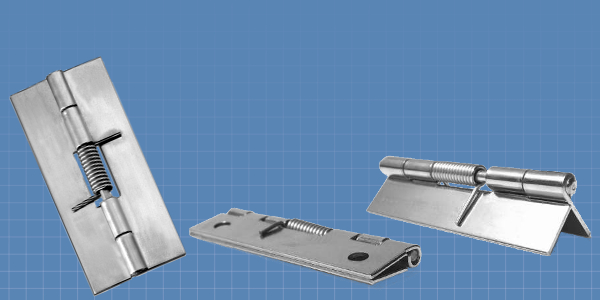

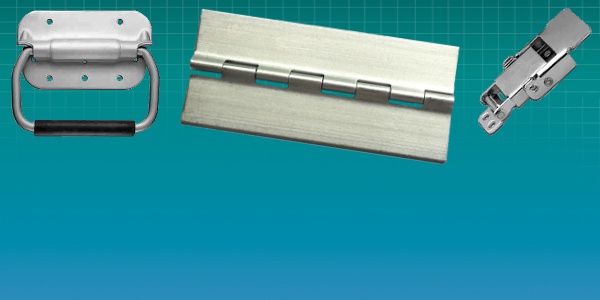

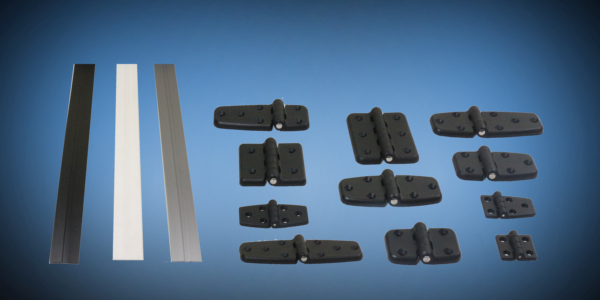

- From piano hinges, butt hinges, and spring hinges to gas springs, draw latches, and door handles, Guden can customize all your industrial hardware needs. -

Capabilities

- Guden provides an array of customizations from cut to lengths, holes, plating and more! Pricing

- Guden prices are always competitive.-

Short Lead Time

- Our shipping department is equipped to ship products the same day they are produced.

General FAQ's

Helpful Information

Didn't find what you were looking for? Here are a few suggestions:

- More information about the products we offer can be found on our Main Products Page.

- The Search Box at the top of each page will give you answers to what we have on our website. Try it out!

- Check the drop down menus across the top or our Product Categories on the left for quick navigation of our website.

- Our Hinge Glossary is packed with tons of information on hinge terminology.

- Done reading? See our products in motion on our YouTube channel.

What are your open hours?

We are open Monday through Friday from 8:30AM to 4:30PM Eastern Time.

What is your minimum order?

We have a low minimum order of $25.00USD.

Do you do split shipments?

In most cases, we can split shipments over several weeks or months, and we also do yearly blanket orders.

Can I ship to two different locations?

Every order can be modified to ship to as many locations as you require.

What credit cards do you accept?

We accept American Express, Discover, Mastercard and Visa.

How do I apply for credit if I don't want to use a credit card?

Simply contact a customer service representative and they'll gladly take your credit application for

review. We require your bank information and 3 trade references.

Can I still place an order after hours?

Sure! You can place an order on our website anytime day or night. It will be processed and acknowledged as soon as we're

back in the office.

Do you provide custom products if one of your listed standard items doesn't fit my requirement?

Yes custom products are available, of course depending on what your requirements are. Contact our customer service

department to submit a drawing or specifications for our review.

How do I return an order?

Contact someone in our customer service department to discuss your return. A Returned Goods Authorization must be

obtained prior to you sending any parts back.